Dr. Wang is associate professor and master supervisor in National Center for Materials Service Safety, University of Science and Technology Beijing. In 2018, he graduated from Institute of Metal Research, Chinese Academy of Sciences and then worked in University of Science and Technology Beijing to date. At present, he is mainly engaged in the research of microstructural regulation and fatigue performance optimization of advanced metal materials (i.e., high-entropy alloy, metallic glass and high-strength metal). He has published more than 40 papers, including Scripta Materialia, Materials Science and Engineering: A, Journal of Alloys and Compounds, etc.

1. 2022, National Natural Science Foundation of China (Youth Foundation Project), Investigation of shear-band evolution and its mechanism during fatigue in amorphous alloys, project leader.

2. 2022, Beijing Natural Science Foundation (General Project), Effect of cyclic loading on structural rejuvenation/relaxation of amorphous alloy and its mechanism, project leader.

3. 2019, China Postdoctoral Science Foundation, A new method for improving the fatigue properties of Zr-based amorphous alloys and its mechanism, project leader.

4. 2019, National Natural Science Foundation of China (Key Project), Macro and micro size effects of fatigue and fracture behavior in additive manufacturing alloys, main project participator.

5.2024, National Key Research and Development Program of China, Study on key service characteristics and fatigue damage of high-speed train wheels, main project participator.

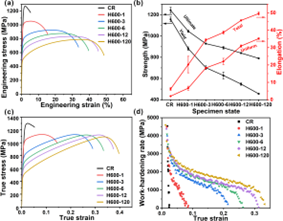

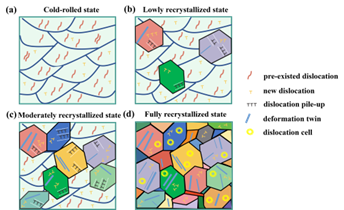

1. Five types of recrystallized fractions, 12.5 %, 45.7 %, 77.4 %, 87.0 % and 100 %, were obtained after cold rolling and annealing at 600 °C for 1 h, 3 h, 6 h, 12 h and 120 h in Al0.1CoCrFeNi high-entropy alloy (HEA). All partially recrystallized structures were comprised of non-recrystallized region with strong {111} <112> texture and recrystallized region with a nearly similar scale of fine grain (~1.22 – 1.57 μm). The partially recrystallized specimens exhibited a good strength-ductility combination, i.e., yield strength increased from ~547.1 MPa to ~881.0 MPa with decreasing recrystallized fractions, while ductility still remained above ~20 %. Based on the law of mixtures, the calculated results of the contributions from multiple strengthening mechanisms to yield strength closely matched the experimental data. It is found that increasing recrystallized fraction leads to enhancing contribution of grain boundary strengthening but weakening contribution of dislocation strengthening and synergistic strengthening. TEM results revealed that plastic deformation in partially recrystallized specimens was dominated by high-density dislocations and deformation twins in grain interior, as well as dislocation planar slip and pile-up near heterogeneous interface; for comparison, dislocation cells and more deformation twins were formed in fully recrystallized specimens.

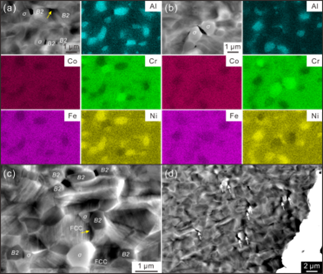

2. A multi-phase fine-grained microstructure was engineered through cold rolling and annealing treatment in Al0.3CoCrFeNi high-entropy alloy (HEA) to obtain an enhanced fatigue property. This alloy consists of FCC matrix phase with an average grain size of ~ 1.13 ± 0.84 μm, and B2 and σ precipitates with sub-micron scale. Their phase fractions are ~ 90 %, ~ 9 % and ~ 1 %, respectively. Stress‒life (S‒N) data indicate that fatigue endurance limit and ratio in terms of stress amplitude are ~ 281 MPa and ~ 0.3, based on stress ratio of 0.1. Good fatigue property is related to high ultimate tensile strength derived from good work-hardening ability and fine microstructure. In addition, activation of deformation twins, blunting of microcracks and deflection of fatigue cracks associated with precipitates are beneficial for enhancement of fatigue resistance. The above results provide theoretical guidance on how to enhance fatigue resistance of HEAs by regulating microstructures.

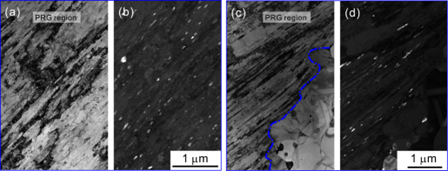

3. We engineer a Al0.3CoCrFeNi high-entropy alloy (HEA) with hierarchically heterogeneous microstructure by cold rolling and annealing treatment, which includes heterogeneous grains, annealing and deformation twins, residual dislocations and B2 precipitates with different morphologies, sizes and distributions. Stress-life (S–N) tests and characterization techniques including scanning electron microscope (SEM) and transmission electron microscope (TEM) were carried out to investigate fatigue properties as well as corresponding mechanisms. It is found that this HEA possesses good strength-ductility combination (i.e., yield strength of ~870 MPa, ultimate tensile strength of ~1060 MPa and ductility of ~26 %) and fatigue resistance with fatigue ratio of ~0.46 under stress ratio of –1. This fatigue ratio exceeds those of most reported HEAs. High strength renders the fatigue deformation mainly occurs in deformation twin regions decorated with B2 precipitates. Surface damage morphologies indicate that fatigue cracks initiate from persistent slip band-like shear bands. In addition, microstructural hierarchy results in the deflected fatigue crack propagation path, which is beneficial for the enhancement of fatigue resistance. Present results offer the guidance on future design for high fatigue-resistant HEAs by manipulating heterogeneous microstructure.

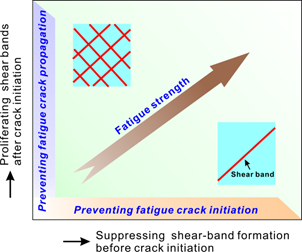

4. The fatigue property of metallic glass (MG) is unexpectedly poor, which limits its application as structural material. The key problem of shear band formation under cyclic stress level lower than yield strength was clarified by free volume theory; then, the shear band-mediated crack initiation and propagation mechanisms were analyzed based on quasi-in situ cyclic method (loading…unloading…observing…); to enhance the fatigue property of MG, we proposed a new strategy through tailoring the microstructure to suppress the shear band formation and then to impede the fatigue crack initiation, in contrast to the previous way of proliferating shear bands.

1. Zhang, Z., Cheng, Y., Wang, X. D.*, Song, S. L., Ren, X. C.*, Investigation on tensile property and mechanism of partially recrystallized Al0.1CoCrFeNi high-entropy alloy after cold rolling and annealing treatment. Mater. Sci. Eng. A, 921 (2025) 147572.

2. Song, S. L., Wang, X. D.*, Zhang, Z., Ren, X. C.*, Investigation on effect of L12 and B2 phases on tensile properties and mechanisms of Al0.3CoCrFeNi high entropy alloy through aging treatment. J. Alloys Compd., 1010 (2025) 177435.

3. Song, S. L., Wang, X. D.*, Zhang, Z., Ren, X. C.*; Characteristic of phase precipitation and its role in grain evolution and mechanical properties of high entropy alloy. Mater. Charact., 218 (2024) 114563.

4. Song, S. L., Wang, X. D.*, Zhang, Z., Wang, Z. B., Ren, X. C.*, Luan, B. L., Enhancing the fatigue property of high entropy alloy by regulating characteristics of grains and precipitates. Int. J. Fatigue, 181 (2024) 108125.

5. Wang, X. D.*, Bai, W. L., Zhang, Z., Wang, Z. B., Ren, X. C.*, Enhancing fatigue resistance of high-entropy alloy by designing a hierarchically heterogeneous microstructure. J. Mater. Res. Technol., 33 (2024) 673–682.

6. Wang, X. D.*, Bai, W. L., Zhang, Z., Wang, Z. B., Ren, X. C.*, Enhanced fatigue resistance of a face-centered-cubic single-phase Al0.3CoCrFeNi high-entropy alloy through planar deformation characteristic. Mater. Sci. Eng. A, 862 (2023) 144499.

7. Wang, X. D., Song, S. L., Zhu, Z. W.*, Zhang, H. F., Ren, X. C.*, Modulating fatigue property of in situ Ti-based metallic glass composites by changing dendrite composition. Fatigue Fract. Eng. Mater. Struct., 45 (2022) 2010-2022.

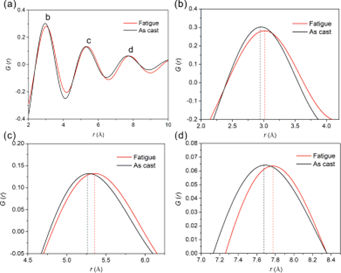

8. Wang, X. D.*, Song, S. L., Zhu, Z. W., Zhang, H. F., Ren, X. C.*, Structural evolution under elastic cyclic loading in a Ti-based metallic glass. J. Non-Cryst. Solids, 577 (2022) 121263.

9. Wang, X. D.*, Zhang, Z., Wang, Z. B., Ren, X. C.*, Excellent tensile property and its mechanism in Al0.3CoCrFeNi high-entropy alloy via thermo-mechanical treatment. J. Alloys Compd., 897 (2022) 163218.

10. Wang, X. D., Song, S. L., Zhu, Z. W., Zhang, H. F., Ren, X. C.*, Fatigue behavior of a Ti-based metallic glass: Effect of sampling location in association with free volume. J. Alloys Compd., 861 (2021) 158432.

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026